Life at the Electronics Research Lab

Back in 2013…

I joined the Electronics Research Lab (ERL), a research and development arm of the Volkswagen Group located in Silicon Valley. The ERL supports the many brands that form one of the largest automotive manufacturers in the world (Audi, Bentley, Bugatti, Lamborghini, Porsche, VW, and more).

Initially hired as an industrial design contractor on the Human Machine Interface (HMI) team, I quickly proved my skills and was hired full-time. I proactively acted as an interaction designer, voice interface designer, creative lead, and project manager across many projects.

Looking back on my accomplishments: I became an inventor, built countless prototypes with a talented team of designers and engineers, led the development of a new website and brand identity, and fostered a culture of innovation.

Drawing on my Cintiq during my first year at the ERL.

With respect to non-disclosure agreements, the majority of my design work is confidential.

Building hardware with the HMI team…

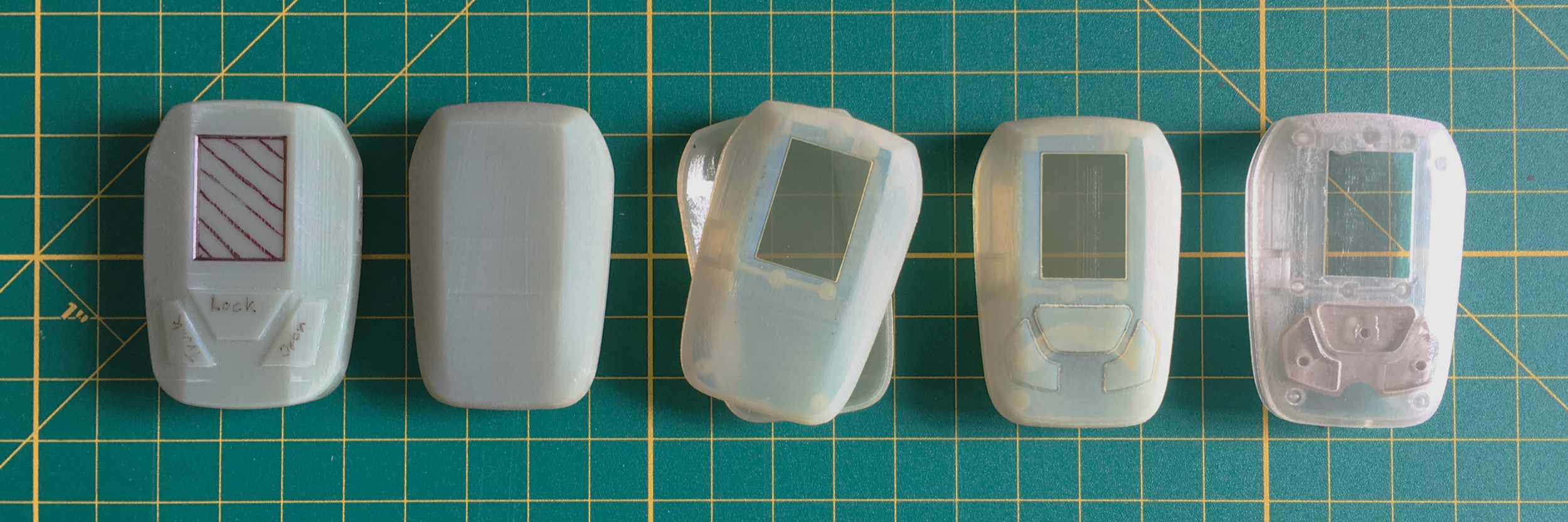

When I started as a contractor, my main responsibility was to support the team by modeling parts and assemblies in SolidWorks. Before long, I was also identifying valuable use cases, scouting for emerging technologies, and presenting showroom quality prototypes.

In a somewhat bizarre reversal of the design process as I knew it from school, our team was sometimes asked to explore a specific technology and brainstorm ways to use it in our vehicles. As a research lab, this work was to shape a product still 5-8 years away. It was an environment which truly fit my natural curiosity and imagination.

We had to take our ideas and turn them into working experiences. I designed parts to package these technologies, working off the existing CAD and measurements of the vehicle, so that it appeared as 'stock' as possible. Sometimes, it was more appropriate to build 'brandless' tabletop demonstrators that we could use to pitch the technology to the various brands without political conflict.

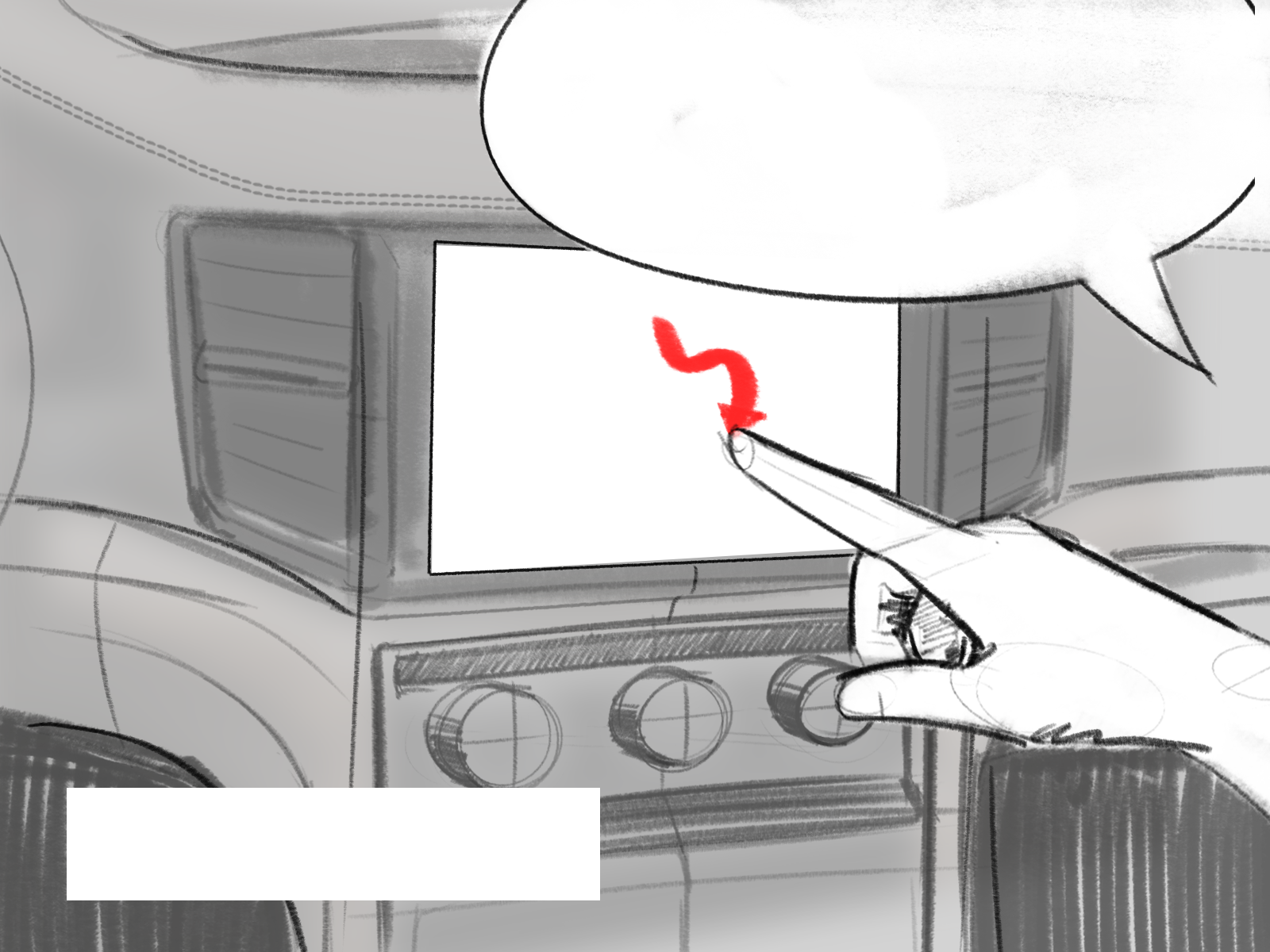

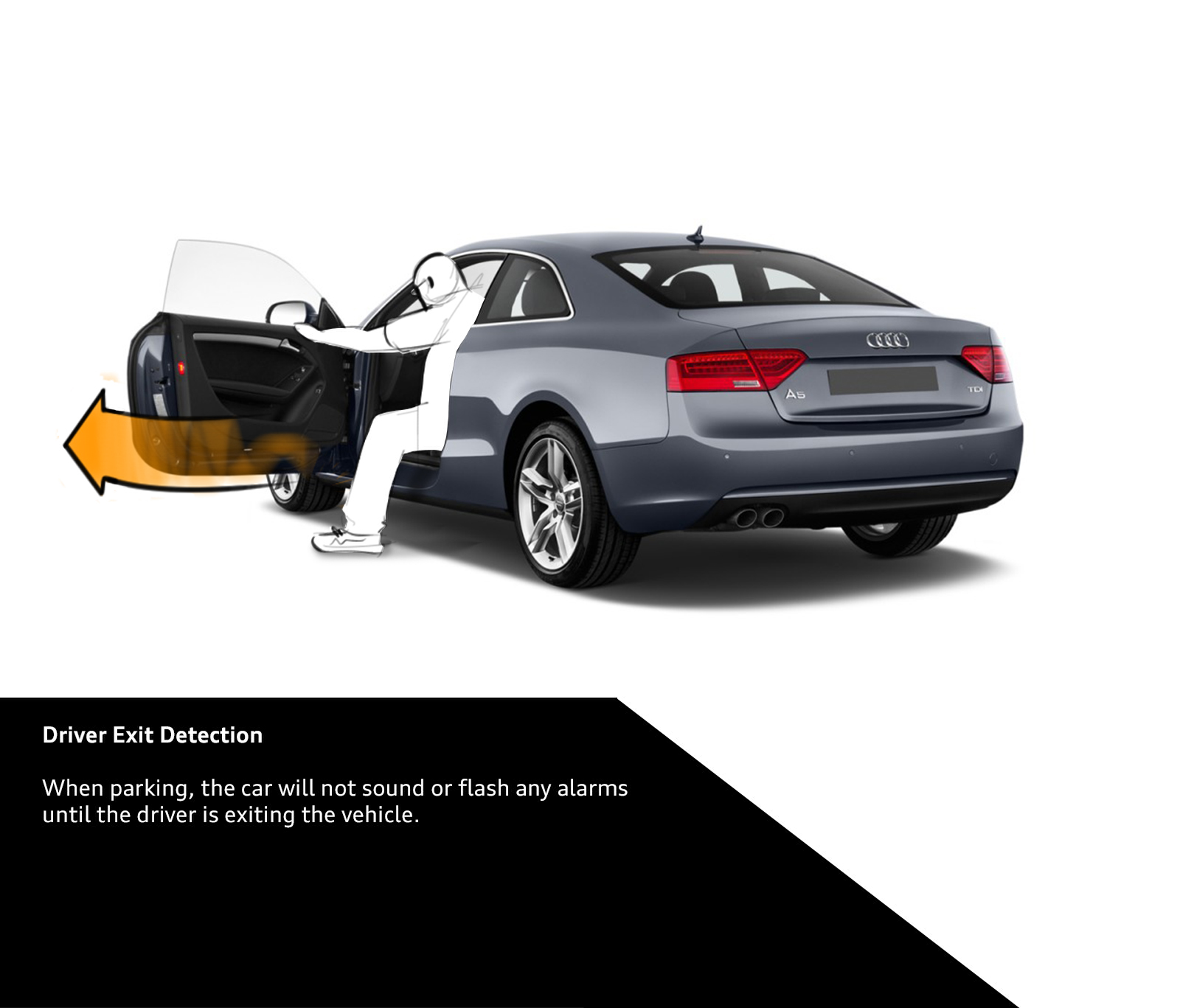

In addition to the work I was doing in SolidWorks, I'd occasionally be asked to sketch storyboards for anything from project proposals to final presentations. These storyboards along with our prototypes would serve to communicate our vision of the user's experience of the future.

It was during this time that I became more proficient at surface modeling and managing complex assemblies. On the rapid prototyping side of things, I was responsible for using and maintaining 3D printers and a laser cutter along with common shop tools to fabricate parts. I also coordinated with local vendors when necessary to have parts manufactured with processes we were not capable of in-house.

A typical day would have me reading through data sheets and working closely with electrical engineers to determine a functional product specification. The back and forth conversation would help us determine the electrical components and the layout of the printed circuit board.

I collaborated with software and electrical engineers to build functional prototypes.

This bezel was modified to fit the dimensions of a prototype screen while maintaining a stock appearance.

Ultimately, I knew that I was at the beginning of a very long process and the vehicle that reaches the customer goes through many hands. What I was physically designing would be destined for the scrap heap, simply due to the nature of doing research at such a massive company. Becoming comfortable with this took time and ultimately a new way to judge success for myself.

Beginning to define the long-term vision…

The same year I joined, I supported another team looking to build a multi-modal interface fully integrated into an existing vehicle. From our brainstorms, I created storyboards to convey our concepts to our project partners.

As the sole user interface designer on this project, I delivered wireframes, assets, and animation specifications to a front-end developer. It was shortly after this project was presented at the annual research show that I was hired as a full-time employee.

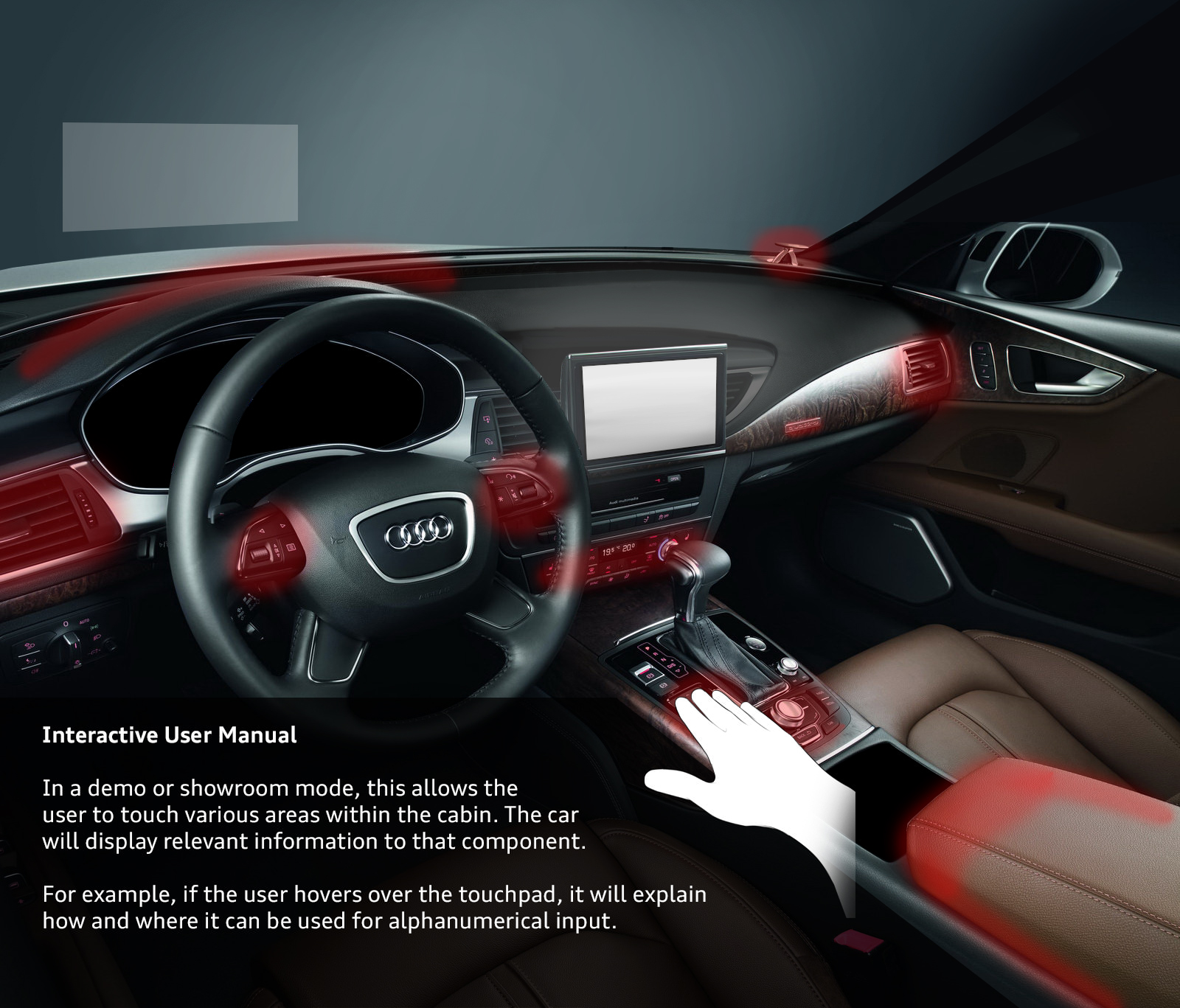

Our team focused on creating next-generation human machine interfaces. How could traditional HMI controls, touch, gesture recognition, eye-gaze, natural language understanding, and more be combined in novel ways to create systems that could respond to implicit and explicit driver intent?

For example, what can we do with sensors that detect where the occupants are reaching? Maybe the interior lighting could be responsive to where the occupant wanted to touch? Maybe we could display information in a heads up display when they reach for a control knob?

Around the spring of 2014, I continued to support the team by designing physical parts and digital interfaces. My manager, seeing my positive impact, asked me to lead two projects. At the ERL, project management was an extra responsibility on top of individual contributions.

I designed several generic digital instrument clusters to support the accompanying hardware technology demonstrations.

In addition to designing the parts, assemblies, and digital interfaces, I also had to keep my team on schedule, communicate with our project partners in Germany, and create ‘VIP’ presentations for the most senior management at the Volkswagen Group.

By the beginning of 2015, I was wearing many hats. But like my growth within the ERL, the lab itself began to take on a new mission and identity. Our director at the time, Ewald Goessmann, made a deal with the top brass of the Group.

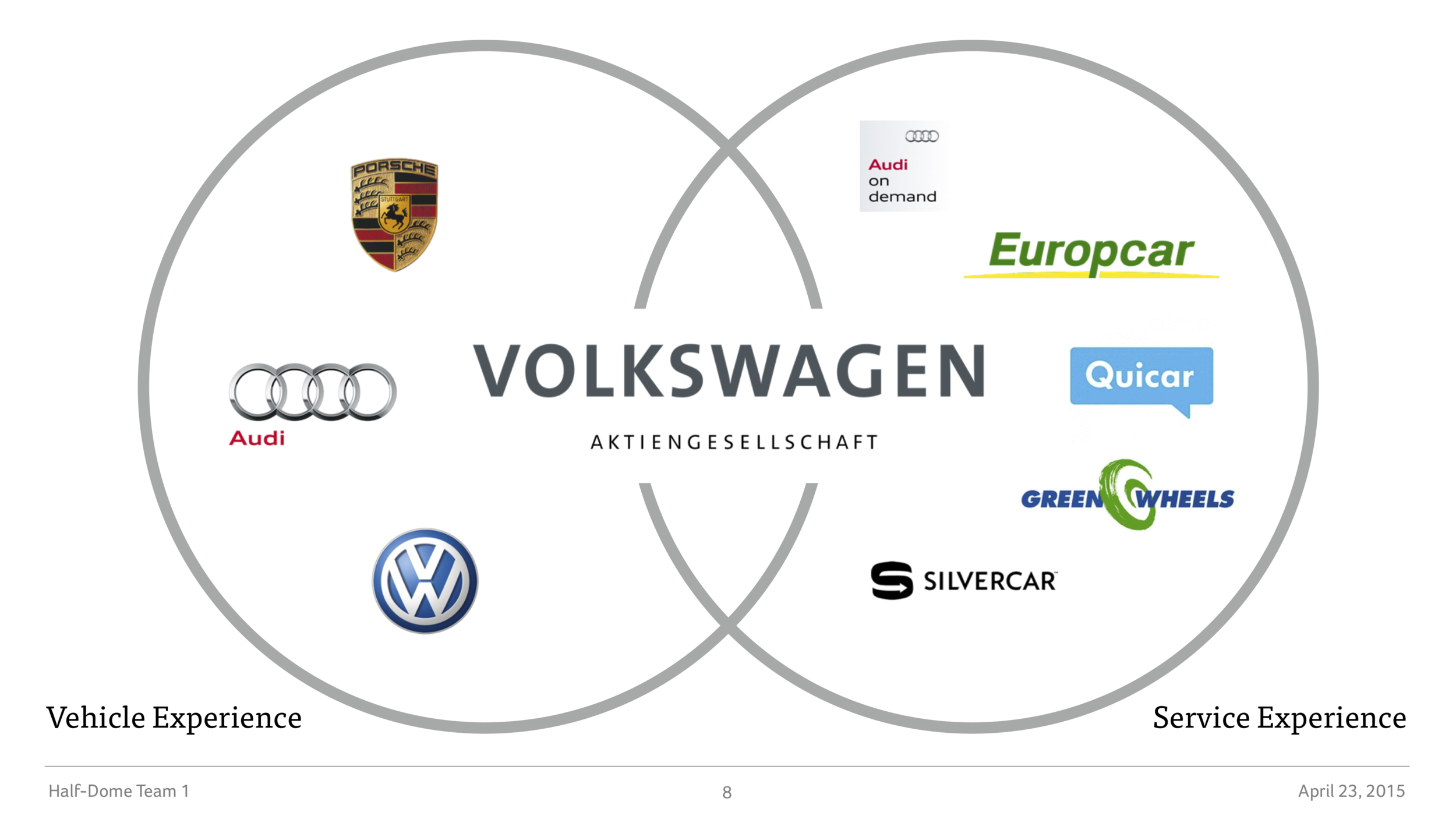

Four teams of five would enter a friendly competition to develop a vision for the future of mobility. They would consist of employees from the ERL, DCC, AIR, and Bay Area design consultancies. The goal was to take a step back and look at the automotive industry from a new perspective.

We brainstormed what the Volkswagen Group could look like in 10 years.

Selected to be on one of the teams, we spent six weeks off-site to develop and deliver a pitch to an audience of high-ranking managers. Our work would go on to serve as a North Star for the ERL over the coming years. It was the first time that the ERL came together to push for concepts like user-centric digital platforms and vehicles designed to be shared.

Shaping a new identity for the ERL…

Meanwhile, the Head of Operations, Tina Unterlaender, had begun a campaign to give the ERL a much needed facelift.

New name, new organizational structure, new location, new website, new paint? Everything was on the table. The vision was simple, the path to reach it was tortuous. So, how did I get involved with this as well?

Do you remember those hats that I mentioned? On top of everything I described earlier, I was also the layout editor of the ERL Newsletter. It would get distributed 2-3 times a year to thousands of people around the world. Turns out it’s hard to find somebody that enjoys layout and typography in a research lab that consists mostly of engineers and mechanically minded designers.

ERL Newsletters from 2003 and 2008 long before I joined.

I tried to bring a level of design professionalism to the layout when I took over. Photo - Ducati

Over the course of the first few issues, I settled on an easy-to-use design system.

Since I was already moonlighting as layout editor, I offered to moonlight as visual designer for a new brand identity as well. As an engineering-focused lab, it was nigh impossible to convince the local managers to allocate all my time towards this side task.

After creating mood and color boards, feedback from the designers at the ERL, and getting in touch with Volkswagen Group Corporate Identity, I set about to create a design system in my spare time.

Taking an evolutionary approach rather than revolutionary, I tried to bring us closer to the Group guidelines while keeping our cool California vibe. Getting approval from management on a new logo, typeface, and color palette was just the tip of the iceberg.

I created presentation templates for PowerPoint and Keynote, worked with IT to make sure typefaces were installed on all corporate computers, became Tina’s in-house interior design consultant, and designed a new website with my talented coworkers.

One of the primary goals in the redesign of the logo was to simplify it and make it easier to use across media.

New presentation templates and fonts were distributed to all corporate computers at the office through IT support.

I provided interior renderings to Tina and the facilities team to help them make decisions.

From start to finish, this process took two years and it was unlike anything I had done up to that point. After three years at the ERL, I finally began to feel like I was having a meaningful impact on the people around me. So, in August 2016, with permission from my manager, I took a month of unpaid leave to reflect, learn a few new skills, and focus on a different community.

When I returned, we officially launched the new identity and website with a special open house presentation. It was truly heartwarming to hear the feedback from my coworkers and to see them proudly sharing the website with their friends and family on social media.

Fostering a culture to outlast me…

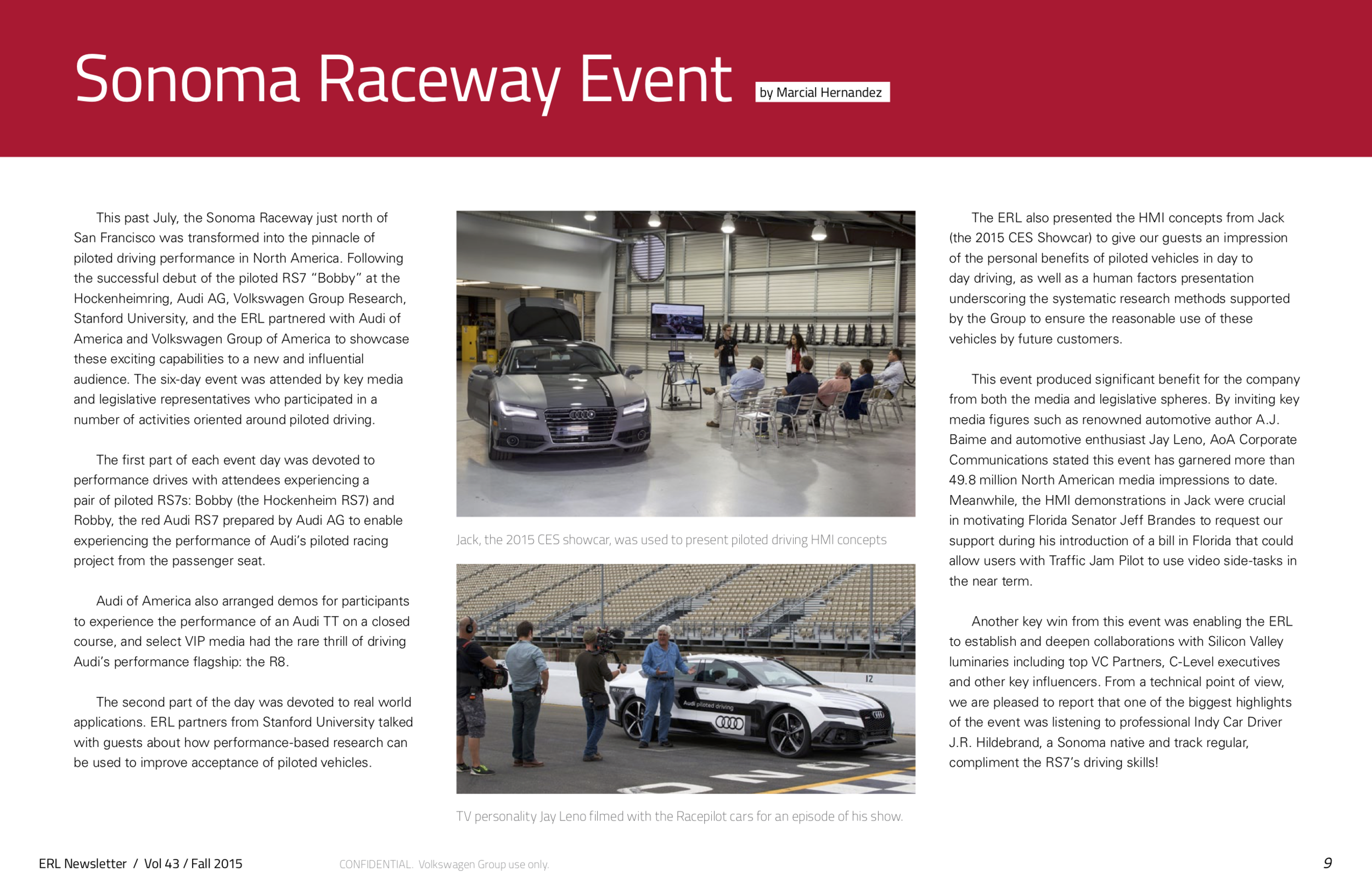

Reinvigorated from my month long ‘break’, I was able to jump back into work with great enthusiasm. My remaining time at the ERL would be full of incredible opportunities like preparing a demo for the VW booth at CES, working closely with the facilities team on office renovations, and working across project clusters to prepare a cohesive story and presentation for our next internal showcase.

Despite the boost of energy, something had changed in me over the four years. Even though I still enjoyed sitting down with my headphones on and crafting something with my hands, I began to find more value in spending time with people. I started to lead workshops on digital design tools, teaching Photoshop to newbies during lunches, and working alongside management to foster a collaborative culture within the ERL.

It was Ewald who helped me recognize the change in myself. He was finishing his assignment and would be moving to China to form a new innovation team for the Group and wanted to meet with me before he left.

I remember him saying that at first he was unsure that a new logo, website, paint, carpets, etc. would really matter to the people. I remember him saying that he has changed his mind, that he sees now how important it is for the spirit of the workplace, that he has witnessed the quality of work improve.

I remember thinking that helping people achieve their greatest potential is what really matters to me.

As this dawned on me, I became anxious to work with clients on a personal level. I had spent a long time in the future and it was time to come back to the present. I began conversations with my manager in the spring to leave after the summer showcase. In July 2017 I handed in my two-week notice, looking forward to the next chapter in my life.